Ultrasonic Scalpel: Comprehensive Usage and Maintenance Guidelines

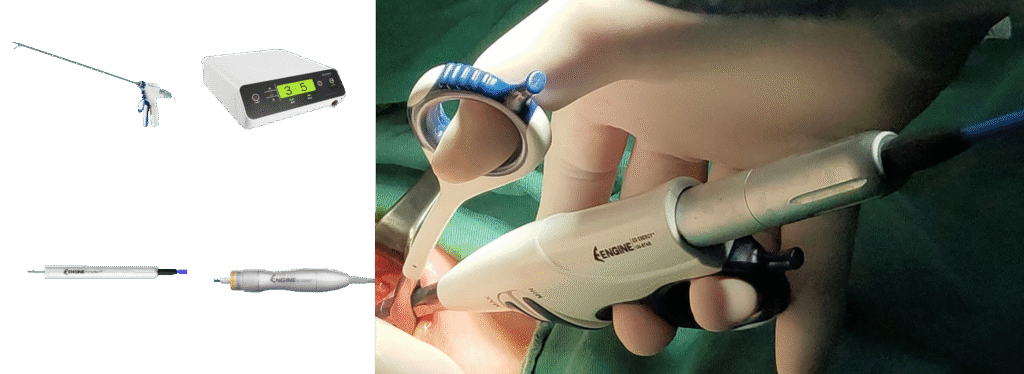

I. Device Composition and Working Principle

The ultrasonic scalpel system consists of a generator, handpiece, blade, footswitch, and cables. It operates at frequencies of 55.5 kHz, converting electrical energy into mechanical vibrations. The blade tip vibrates longitudinally at amplitudes of 50–100 μm, enabling simultaneous cutting and coagulation through:

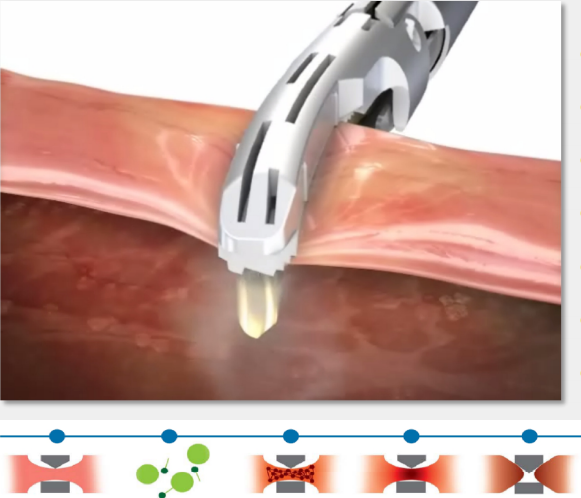

Protein denaturation: Vibration friction generates localized heat (50–100°C), sealing vessels ≤3 mm.

Cavitation effect: Ultrasonic waves fragment tissue via microbubble implosion

II. Preoperative Verificatio

Integrity Check

Inspect silicone seals on the handpiece for cracks (critical for vibration transmission)

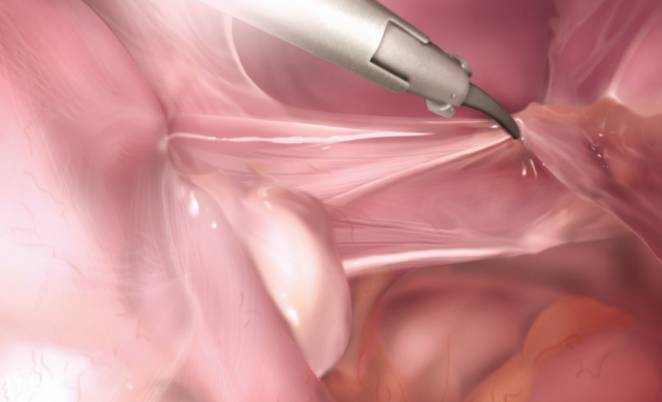

III. Intraoperative Protocols

A. Tissue Handlin

Optimal clamping force: 15–20N (excessive force reduces vibration efficiency).

Cutting sequence:

Vascular bundles: Use pulsed mode (2-sec activation/1-sec pause) to prevent lateral thermal spread >0.3 mm.

Adipose tissue: Activate after compression to expel lipids (reduces smoke by 92% vs. electrocautery).

B. Thermal Management

Continuous activation limit: ≤7 seconds per application.

Blade cooling protocol:

Immerse in saline every 10 minutes; activate while agitating to dislodge debris.

Critical: If blade temperature exceeds 80°C , cease use immediately to prevent tissue carbonization.

C. Safety Contraindications

Avoid in calcified tissues: Ultrasonic energy reflects off bone, risking blade fracture.

Prohibited near pacemakers: May induce electromagnetic interference even in "monopolar-safe" mode.

IV. Post-Procedure Processing

A. Immediate Cleaning

Pre-soak: Immerse in multi-enzyme solution (concentration: 8 mL/1000 mL water) at 40°C for 15 minutes.

Manual cleaning:

Use lint-free cloth soaked in neutral pH detergent.

Prohibited: Wire brushes or abrasive tools (damage titanium alloy coating)

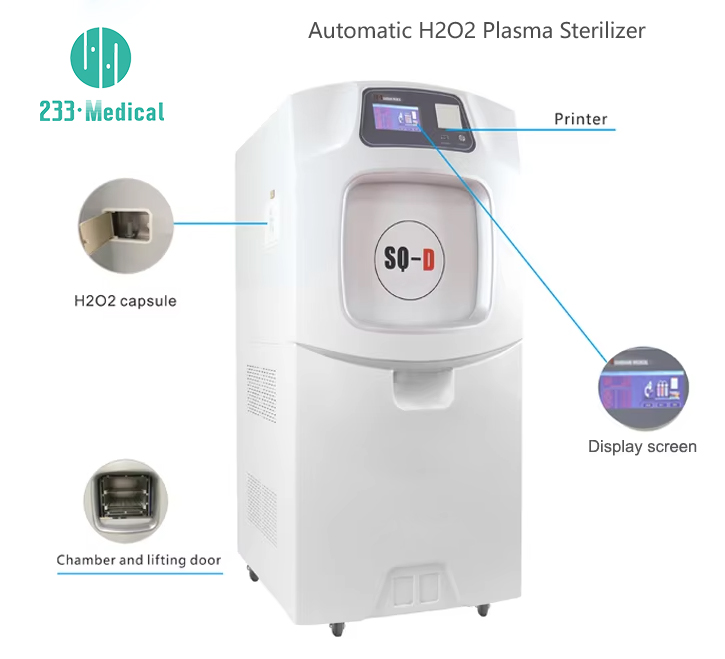

B. Sterilization Methods

| Method | Parameters | Lifespan Preservation |

| Low-temperature plasma | 135°C, 45 min, H₂O₂ concentration 6 mg/L | ★★★★★ (50 cycles) |

| Ethylene oxide (EtO) | 55°C, RH 60%, 4-hour exposure | ★★★★☆ (40 cycles) |

| Glutaraldehyde immersion | 2% alkaline solution, 10-hour immersion | ★★☆☆☆ (15 cycles) |

Note: Steam sterilization >121°C permanently degrades piezoelectric crystals.

V. Performance Validation

Post-sterilization test:

Connect to generator and select "Self-check" mode

Acceptable vibration variance: ±5% from baseline frequency.

Reject blades showing amplitude drop >10% (indicates internal fatigue).